I had read quite a bit about this specific model, and when i could get a very good deal i grabbed them.

For me these Kukri Machetes have a useful size (they fit inside my daypack), with around 2.8 mm blade thickness they are quite rigid for a machete and certainly not flimsy or wobbly, the steel so far seems well hardened, and the handle fits my hand quite well, while the softer PVC plastic material dampens shock quite effectively.

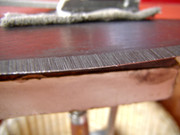

The factory edges however are only rudimentary, coming with at best a heavily burred or at worst a not even apexed "edge", which is then simply covered in a black bake-on coating.

The backs of the blades are very rough as well, with pieces of burring that were almost sharper than the main edge, and a chequered handle surface that can create blisters with prolonged use.

However with a bit of work & a few simple tools all this can easily be solved, and then the true quality of these very useful blades will come out.

First i used an F.Dick coarse double cut basterd file to completely remove the heavily burred (and most likely burned) apex.

Then i used the same file to make a rough convex shape up to the now flattened apex, followed by an Oberg smooth file to refine the surface up to a new apex, but without creating a burr.

Then i used 3 grits of wet & dry with WD40 as a lubricant on a semi-hard rubber backing to smoothen the convex shape even more, bringing the apex to a burr on 180 grit and refining it through 240 grit and 400 grit.

The burr was then taken off on the Tormek leather wheel with some PA-70 paste.

You can click 2 X on each pic for a bit more detail.

One of the kukri's clamped down with it's heavily burred factory apex already filed flat, but with the coarse +/- 45 degrees factory V-bevels bevels still remaining:

Starting the new convex edge by filing away the shoulders of the factory edge, then slowly working towards the flattened "apex":

I think this was actually the first one i did, later this became my tester/user to see how thin i could reasonably take the convexing process.

Almost there btw.

Number two now done with the bastard file, and starting with number three:

During sanding on respectively 180, 240, and 400 grit wet & dry SiC and WD40 as a lubricant backed with an old piece of fiber reinforced rubber conveyor belt.

The new apexes fit almost perfectly in the 30 degrees inclusive slot of the Tormek WM200 Angle Master.

Removing the chequered handle surface with a coarse wood rasp to give it a much more "handpalm-friendly" finish.

Right after the wood rasp treatment on the right, and one that has already seen several days of use on the left.