I own several vintage Gerbers in M2 steel, both outdoor & kitchen models, and this Durendal slicer model from the '60's does duty in our kitchen.

Opening all kinds of paper & plastic food packages, slicing bags with espresso beans, cutting up larger fruits like melons & pineapples, slicing bread loafs and hamburger buns without crumbling, cutting sausages, etc.

Not every day, but at least several times a week.

I bought this Gerber about 2 years ago on E-Bay completely blunt, so i reprofiled & sharpened it with a SiC grit Paper Wheel, then refined the edge with 15 micron diamond compound on a second Paper Wheel, and then again with 6 micron diamond compound on a third Paper Wheel.

The tiny burr was removed with a fourth Paper Wheel coated with 0,25 micron diamond compound.

The idea was to get something of a semi-polish that would protect the exposed M2 edge better against corrosion issues during kitchen use, while still having some degree of bite.

The knife was then used for about 2 years in our kitchen, and when not in use stored on a magnet strip on our kitchen wall.

After those 2 years the edge only had a few very minor dings/flat spots in it (in the tiny belly area), but it could still shave the hair on the back of my hand on skin level quite well with about 90-95 % of the edge.

When cutting tomatoes however the edge tended to slide a bit over the skin before it started to cut.

The main reason for this kind of edgeholding is of course the fact that most of the edge on a slicer like this never touches a cutting board, only the belly area does, but the M2 steel performed quite admirably in my book.

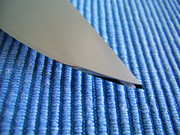

A few weeks ago i resharpened the edge, this time only with 15 micron diamond compound, then deburred with 0,25 micron diamond compound, as i want to try the knife with some more bite.

Will have to find out if there will be corrosion issues or not.

So far i've only used it on food packaging (both paper & plastic, no fruit or other things yet), but here are a few pics how the knife & edge look now.

The edge feels sticky and is still treetopping sharp.

Specs:

Blade steel: hard chromed M2 steel

Hardness: 60-62 HRC

Handle material: cast on aluminum, chromed.

Overall length: 11.61 inch (29,5 cm)

Blade length: 6.5 inch (16,5 cm)

Blade thickness: 1,36 mm in front of the handle tapering to 0,84 mm close to the point

Thickness behind the edge: 0,5 mm

Edge angle: +/- 30 degrees inclusive, slightly convex